Framo Pump Operation Manual

Posted : admin On 29.10.2019Author(s) FRAMO Publisher FRAMO Date 2003 Pages 157 Format pdf Size 61 Mb The present training manual has been specifically prepared and officially released by FRAMO professionals to be used by all people who are going to take the associated training courses. Subject courses are run by the company on the regular basis and FRAMO members are doing their best to transmit their technical knowledge to anyone interested. The effectiveness of all professional training courses that is offered by FRAMO company has already been proven everywhere. The present publication contains all information required to be possessed by all interested people who are willing to enroll in the above stated training courses.

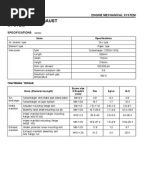

Framo Pump Operation Manual.pdf Free Download Here FRAMO PUMPS FRAMO PUMPS Operation and Maintenance Manual with Spare Parts List. 'FRAMO' Hydraulic Cargo Pumping System Course. Stripping operation, cargo pump evaluation. Hands-on practice on the dismantling of the FRAMO cargo pump.

The users will find everything that they need there, including the location of the courses and training seminars. The training that is deal with in the present booklet will enable the learners to conduct the operations at the time of the cargo discharging and stripping, heating of the cargo and tank washing in a correct way, to perform proper periodic maintenance/troubleshooting of the main components of the system. It starts with the part describing the submerged cargo pumps produced by FRAMO, and basic hydraulic systems together with their associated components plus providing some info on the tanker design using the Frank Mohn system of cargo pumping.

Framo portable cargo pumps for chemical tankers- Care and storage onboard Framo portable cargo pumps for chemical tankers- Care and storage onboard Framo portable submersible pumps, are provided on chemical ships and other specialised liquid cargo carriers, for discharging cargo in the event of a main cargo pump failure. The pumps are usually hydraulically driven and lowered directly into the tank generally through a tank cleaning hatch. The portable pumping equipment must be stored easy accessible in a clean and dry area. The concentric hose can be stored on a suitable hose reel, or on brackets on the bulkhead, or lying in a shelf. The pump and hoses must always be safely supported and fastened in order to avoid wear or damages due to ship movements. It is especially important that the hoses are not hanging or laying over sharp edges, or that sharp objects are placed upon them. Fig:TK 150; Remove impeller to check cofferdam.

TK150: min. Bending radius: 650 mm The equipment box is delivered with a bracket for installation in a fixed location close to the portable pump. The portable winch must be safely supported and fastened in order to avoid wear or damages due to ship All necessary safety precautions relevant to the actual cargo being handled are to be observed and permission obtained from the local port authorities before operations are commenced.

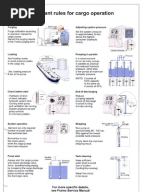

It is a good practice to shutdown the hydraulic oil pressure system before connecting and disconnecting hydraulic hoses of portable hydraulic driven emergency pumps. Fig:TK 80; Cofferdam plug remove to check for leakage Testing of the portable pump.

The pump discharge flange to be equipped with a blind flange. Install a “Minimess” test coupling and a “Minimess” test hose (equipment in the Test kit) on the blind flange. Hoist the portable pump into a drum containing fresh water. Connect the extension hoses to the hydraulic ring line. First connect the return hose, then connect the pressure hose. Start the pump slowly, and run with low speed.

Check if the pressure gauge on the control valve is working. When water is flowing from the test hose, connect a pressure gauge. Increase speed until rated discharge pressure, or to max. 5 bar discharge pressure. Operate at this speed only for a short period. Check for hydraulic oil leakages on all connections.

Reduce speed and stop the pump. Disconnect the extension hoses from the hydraulic ring line. First disconnect the pressure hose, then disconnect the return hose. Drain off approximately one cup hydraulic oil from each of the extension hoses and from the concentric hose. Check cofferdam on pump head for leakage. TK 150: remove impeller nut and raise pump head to vertical position. TK80: remove cofferdam plug and tilt pump to horizontal position.

If excessive leakage is noted, actions must be taken. Make a visual control of the complete unit. The cargo hose for the portable pump to be tested and maintained according general in forced rules and procedures valid for cargo hoses onboard the vessel. Fig:Framo portable pumping system Purging of the cofferdam is one of the most important operations to be done when operating a submerged Framo Cargo Pump.

This is the only way to check the pump’s seals, and thus the conditions of the pumps, is by purging possible leakages in the cofferdam. Lf this is done and necessary action in case of large leakages is taken, trouble free operation of the cargo pump is obtained therefore it is important to - Purge the pump’s cofferdam regularly. Log and evaluate the purging result. A clean and open cofferdam gives trouble free cargo pumping. Fig: Pressure test of FRAMO submersible Cargo Pump How to perform pressure test of FRAMO submersible Cargo Pump If the purging routine has detected a cargo leakage (more than 2 litre / day), and the evaluation indicates that action must be taken, first thing you have to do is to identify the leakage.

The best way is to pressure test the pump’s cofferdam. Cargo Leakage If a cargo leakage is detected the complete cargo pump’s cofferdam has to be pressure tested to identify the leak. The crew on some ships start to automatically change the pump’s cargo seal as soon as there is a cargo leakage - although the leak may be somewhere else.

This is waste of time and money. So always identify where you have a leak first! The cofferdam can be pressure tested by blinding off the purging medium relief valve by means of a rubber gasket. Dismantle the cofferdam’s riser pipe flange on the top cover plate and install a test flange with pressure gauge (see figure 1). Connect the purging medium to the test flange and increase the pressure to 3 bars. After approximately 5 minutes check all flanges around the cargo seal, riser pipe and all other connections for possible leakages. Use soapy water for better detecting of the possible leakage.

Note: If the cargo leakage is not possible to identify and the 3 bar pressure is stabilized for a long period of time during the pressure testing, it is still possible that the cargo seal in the pump is worn out and have to be changed. The reason could be that the 3 bars pressure in the cofferdam is pressing the upper lip (facing the cofferdam) around the pump shaft. Dismantle the cargo seal for control.

If this is not the case and the cargo leakage is not possible to detect, you have to split the cargo pump and pressure test the main components separately. Hydraulic Oil Leak If the cargo pump has a hydraulic oil leak you normally have to split the pump to identify the leak. A hydraulic oil leak is very rare under normal conditions, but if a hydraulic oil leak does occur, there could be three reasons: a) Hydraulic oil seal - the life time is normally very high (10.000 running hours). B) Crack in pipe stack - can occur if the cargo pump is vibrating heavily for some abnormal reasons.

C) Corrosion attack in the seal ring grooves can occur after long service. Good practices Acid cargoes: After discharging and purging is finished, it may be an advantage to circulate fresh water through the cofferdam to remove all residues after a leakage. Phenol, caustic soda etc.: A circulation of hot water through the cofferdam can avoid clogging. Polymerising cargoes (TDI, MDI): Fill cofferdam with dioctyl phthalate(DOP) to limit the risk of blocking the cofferdam. Crystallizing cargoes (molasses, etc.): Fill cofferdam with fresh water. The cofferdam may also be arranged with a small water circulation Related Info Other info pages These instruments, often referred to as Draeger tubes, normally function by drawing a sample of the atmosphere to be tested through a proprietary chemical reagent in a glass tube. The detecting reagent becomes progressively discoloured if a contaminant vapour is present in the sample.

The length of the discoloration stain gives a measure of the concentration of the chemical vapour which can be read from the graduated scale printed on the tube. Detector tubes give an accurate indication of chemical vapour concentration, whatever the oxygen content of the mixture: The voyage orders will contain heating information, if heating is required. As a rule the final heating instructions are given by the Shipper in writing to the Master / Chief Officer in the port of loading. If those written instructions are not given, the master should request them and issue a Letter of Protest if they are not received at departure. 2017 bls pocket guide. In the latter case the management office should be immediately informed.:Temperature sensors are fitted so that the temperature of the cargo can be monitored, especially where required by the IBC Code. It is important to know the cargo temperature in order to be able to calculate the weight of cargo on board, and because tanks or their coatings often have a maximum temperature limit.

Many cargoes are temperature sensitive, and can be damaged by overheating or if permitted to solidify. Sensors may also be fitted to monitor the temperatures of the structure around the cargo system.:In order to maintain a proper control of the tank atmosphere and to check the effectiveness of gas freeing, especially prior to tank entry, several different gas measuring instruments need to be available for use. Which one to use will depend upon the type of atmosphere being measured.:The accuracy required of chemical carrier level gauges is high because of the nature and value of the cargo. To limit personnel exposure to chemicals or their vapours while cargo is being handled, or during carriage at sea, the IBC Code specifies three methods of gauging the level of a liquid in a tank - open, restricted or closed:Certain cargoes require the designated tank to be fitted with a separate high level alarm to give warning before the tank becomes full.

The alarm may be activated by either a float operating a switch device, a capacitive pressure transmitter, or an ultrasonic or radioactive source. The activation point is usually pre-set at 95% of tank capacity.:Oxygen analysers are normally used to determine the oxygen level in the atmosphere of an enclosed space: for instance, to check that a cargo tank can be considered fully inerted, or whether a compartment is safe for entry.:Ships carrying toxic or flammable products (or both) should be equipped with at least two instruments that are designed and calibrated for testing the gases of the products carried. If the instruments are not capable of testing for both toxic concentrations and flammable concentrations, then separate sets of instruments should be provided.:An important feature of many modern measurement and control instruments is the ability to signal a particular situation. This can be a main operational alarm that gives an indication of a pre-set situation such as liquid level in a tank, or a malfunction alarm indicating a failure within a sensor's own operating mechanism.

The designs and purposes of alarm and shutdown circuits vary widely, and their operating system may be pneumatic, hydraulic, electrical or electronic. Safe operation of plant and systems depends on the correct operation of these circuits and a knowledgeable reaction to them.:Gas freeing onboard chemical tankers is required for entry into cargo tanks, for hot works or washing for clean ballast tanks. Gas Freeing is one of the most hazardous operations routinely undertaken onboard a Chemical Tanker and the additional risk created by cargo gases expelled from the tanks, which may be toxic, flammable and corrosive, cannot be over-emphasised.:Blowing and pigging of pipelines at terminals poses inherent risks for the terminal and a chemical tanker. Frequent damages to tanks have occurred. If there are doubts about the shore operation or signs of problems ashore the OOW must immediately request clarification. Reference publications. Equipment Manufacturers Instruction Manuals.

Framo Pump Operation Manual Pdf

MARPOL – 73/78 (latest consolidated edition). International Safety Guide for Oil Tankers and Terminals (ISGOTT). CFR 33 parts 125 to 199. Ship to Ship Transfer Guide (Petroleum). MSDS for particular cargo carried. Chemical Tank Cleaning Guide Main Info pages!. Chemicaltankerguide.com is merely an informational site about various aspects of chemical tankers and safety tips that may be particular value to those working in: Chemical Handling, Chemical Storage, Liquefied Chemical Suppliers, Chemical Shipping, Chemical Transportation, Chemical Terminals, Bulk Chemical Services and Chemical Processing.

Framo Pump Operation Manual

If you are interested in finding out more about chemical tanker guideline please visit IMO official website. For any comment please Copyright © 2011 All rights reserved.